connect.

Data acquisition and visualization

The function packages of our autfactory are designed to build on each other

and can be expanded at any time.

The highlight of our licensing model:

Unlimited number of users and variables.

WITHOUT additional costs!

Quality & inspection Planning

Test data evaluation

Gauge management

Calibration

To ensure the high quality requirements of your production, continuous calibration of the test equipment is necessary. autfactory offers the possibility to manage the test equipment and its maintenance and calibration intervals. Dynamically calculated intervals automatically show you when calibration is due. This allows you to keep track of all upcoming calibrations. The execution of the calibration is supported by step-by-step instructions. In addition, the operator is indicated to insert the respective calibration standard, reference or master part in order to check the measuring device.

Your benefits:

Pass check

The pass check allows an additional validation of the processing sequence. It is a product-, type-, and post-process-dependent test (e.g.: additional review of previous work processes). The respective test rules can be individually defined and easily created by the user. The workflow and the proper execution of the process being checked. “Pass” means that everything was fine at the previous station. In case of deviations, a part is rejected as “Fail”.

Your benefits:

Production order management

Workflow management

Consideration, condition & plausibilities

Order Management

The order management enables the central management of all production orders directly in autfactory. The orders to be produced can be entered directly in the system with the necessary order data such as quantity, variant, etc. In this process, each part produced is assigned to an order. This function offers the possibility to generate order-based evaluations and ensures complete traceability of all order bookings. When using appropriate connections, the orders can also be synchronized with the ERP system.

Your benefits:

Product, Type, Variant

With autfactory it is possible to create an unlimited number of products, types and variants easily, without programming knowledge.

Product: A product is defined by the user. It can be a functional complete unit or a part of it. (e.g. car or gearbox, cell phone or transmitter unit)

Type: A type is the characteristic of the unit or part. (e.g.: diesel or gasoline, automatic or manual transmission, IOs or Android).

Variant: The variant specifies individual versions. They mostly exist in parallel (e.g.: displacement 2l or 3l, 6 or 8 gears)

Your benefits:

Inventory management

Batch management

Production traceability

Worker and batch management

The recording of workers and batches leads to transparency in production. It is recorded at what time, in what way, at what place and by whom a product was produced. Thanks to complete traceability, it is possible to take more targeted corrective actions. Early termination of delivery in the case of faulty batches can, for example, ward off possible claims for damages. The identification of error causes in the event of a complaint also makes a significant contribution to increased production reliability as part of the continuous improvement process.

Your benefits:

Document

management

Workflow

management

Event

control

Process

interlock

Data

provision

Mapping of the manufacturing structure

Thanks to the clear tree structure, you can map the entire value chain in one system. Any grouping and structuring of companies, production sites, areas, lines, cells and stations is possible. Thanks to the drill-down navigation, you can go from the general overview to detailed information on the individual stations or products with just a few clicks. autfactory is also aligned with the standards of ISA-95 (standard for the integration of corporate and operational management levels). Among other things, this defines the interfaces to higher-level and lower-level systems.

Your benefits:

Custom Dashboard

You can easily customize the dashboard of your autfactory to suit your needs. With the help of widgets, you can comfortably edit your personal overview page using drag & drop and display the evaluations or KPIs that are most important to you. This means that you always have an overview of the performance of your production and can quickly obtain information about the current status of each individual production line. The settings are saved per user, allowing each user to customize the interface according to their personal requirements.

Your benefits:

Digital Worker Guidance

Thanks to digital worker guidance, it is possible for you to record recurring work processes in digital form and retrieve them where they are needed.

Whether as a tool for describing setup procedures, as a rework description, or for displaying maintenance instructions. With the simply described step-by-step instructions, operators are shown the individual work steps. Only when the current step has been marked as completed, the next instruction is displayed.

Your benefits:

Alarms, Warnings, Notifications

Via the notification system, autfactory informs users about deviations from the normal state. This function helps you to make the right decisions quickly in critical situations and thus avoid production downtimes and plant shutdowns. Due to the historical recording of all alarms and messages, there is the possibility of alarm evaluation in defined time periods. This allows the causes of errors to be identified and eliminated. In addition, an automatic e-mail notification can be stored for relevant events such as fault messages.

Your benefits:

Load

termination

Capacity

termination

Sequence

planning

Bottleneck

processing

Order

release

Sequence Control

The sequencer allows you to freely configure the assembly or test sequences without any programming knowledge. The creation of variable test sequences, which are processed one after the other, ensures the control of complex process sequences. The mapping of special processes is also possible. If there is only one station or test area, you only need the sequencer for sequence control. If there are several stations or test areas, the process flow control module is also required to control the flow between the individual stations.

Your benefits:

Process Flow Control

The process flow control allows you to define processes and dependencies in lines on a type-specific basis and to pass on commands to the control. Specifically, this regulates how components are fed through the complete system. These include machining releases, selection of the next station, special processes such as calibrations, or decisions in the case of branching.

This allows you to ensure, that only components that have positively passed all inspection stations can be packed or delivered.

Your benefits:

Line Designer

The most important information at a glance. The line designer allows you to create a schematic representation of the production flow. Arrange the stations freely according to your plant layout. Even complex, interlinked plants can be easily modeled with the line designer.

Deviating cycle times or failures at the station can be detected immediately by color coding. Thus, you keep track of your complete plant status.

Your benefits:

Energy data

guidance

Energy data

management

Consumption

evaluation

Are you also confronted with high energy costs, but do not have an exact insight into your consumption behavior? Increase your transparency! With autfactory, you can easily track how much electricity was needed to produce a particular part. Thus, it is also possible to compare the power consumption between individual product groups. Transparency of energy consumption can also ensure that energy is supplied in line with demand, for example by switching off machines during the lunch break to avoid idle power consumption. Thanks to the seamless data traceability, a basis for the verification for ISO 50001 is created.

Your benefits:

Qualification

management

Time account

management

Deployment

planning

Shift Calendar

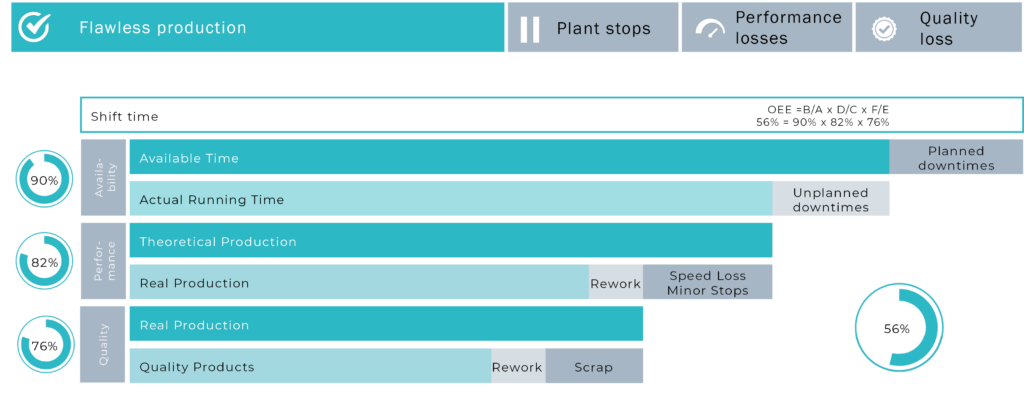

The shift calendar is used to plan production times and scheduled downtime, such as breaks or maintenance. The resulting maximum available production time is subsequently used to calculate various key figures.

The function for creating teams in the shift calendar allows the most accurate calculation of key figures (3 people per shift, for example, give a different OEE result than 5 people). Thanks to the useful template function, the creation of serial appointments is also done within a few clicks.

Your benefits:

User Management

Who is allowed to access which information and perform which actions? User management plays an important role in the course of production security. Manage access permissions quickly and easily with our central user management. Define who is allowed to view, edit, or even delete individual functions (e.g. parameters). The detailed gradation of rights ensures that only authorized persons may perform sensitive settings. Workers can log on to autfactory using a regular user name and password, or with a scanner or smart card.

Your benefits:

Order data

Machine data

Personnel hours

Test data

Charts

By using charts, it is possible to bring any kind of data into an optimal and clear presentation form. Trends, correlations or conspicuous features can be recognized more easily. The created charts can then be exported as .png, .jpg, .svg or .pdf files.

Your benefits:

Report Designer

The Report Designer allows you to create evaluations and reports according to your needs. Numerous editing options are available: From inserting your company logo, to selecting and placing a wide variety of data fields. Thanks to the intuitive user interface, report creation is self-explanatory and can be performed without training. You can name the settings of your self-created reports individually and save them as a template.

Your benefits:

Process Data Tracing

More transparency – better decisions. Thanks to the seamless recording of all connected process data and the option of automatic serial number generation, all parts can be traced back to batch size 1. The collected data forms the basis for evaluations, trend analyses and key figure determinations. Among other things, this can be used to identify the causes of problems in individual production machines. Addressing these issues proactively leads to sustainable productivity and efficiency improvements.

Your benefits:

Parameter Management

The parameter management of our autfactory makes it possible to set, manage and, if necessary, extend the individual parameters for lines, their products and associated types. Audit trails ensure 100% traceability of every parameter change. A practical e-mail notification service immediately informs responsible persons about settings that have been made. In addition, a flexible rights system secures access from all process levels down to individual parameters.

Your benefits:

Adhoc query

Data is becoming increasingly important. With a large amount of data, it is often difficult to keep track of it all. With the Adhoc query, it is possible to create a simple & interactive compilation of evaluations of all data. These can be output as a table, chart, PDF report, data export or CSV as required.

Users can easily and effortlessly select the data that is relevant to them. This allows insights to be visualized quickly, accelerating the decision-making process across the enterprise. The queries can be created by the user without any programming effort.

Your benefits:

Key order figures

Resource metrics

Technical process key figures

OEE Analysis

Let’s take your production to the next level together. Thanks to the automated data acquisition of autfactory, causes of loss can be identified, and thus unused potential can be detected. With the help of the data obtained, processes for continuous improvement can be initiated

(CIP) to permanently increase productivity and optimize output. Whether in the home office or in production, on the tablet or on the PC – all data can be evaluated directly live. All you need is a web browser.

Your benefits: